In a world where companies like Amazon, Toyota, and Google set the gold standard for efficiency and innovation, operational excellence is no longer optional—it’s the key to survival. Amazon’s relentless focus on automation and streamlined logistics has revolutionized e-commerce, while Toyota’s lean manufacturing principles have been adopted across industries.

Google, on the other hand, continuously optimizes its internal workflows to drive both creativity and productivity at scale. These industry leaders demonstrate that operational excellence isn’t just about cutting costs; it’s about building adaptable, resilient businesses that thrive in an era of rapid change.

At CCO, we specialize in helping businesses identify and eliminate inefficiencies through data-driven strategies. In this article, we’ll explore the foundational elements of operational excellence, discuss proven tactics for creating more agile processes, and offer guidance on sustainable improvements that deliver value over the long term.

Understanding Operational Excellence

Operational excellence is a comprehensive approach to business management that emphasizes consistency, reliability, and continuous improvement. It goes beyond mere cost reduction or superficial process tweaks; it requires a deep cultural and organizational shift that enables teams to continually assess, refine, and optimize their activities.

- Customer-Centric Focus: A key principle is understanding and meeting customer needs effectively. By designing workflows that prioritize quality and reliability, companies can exceed customer expectations.

- Process Standardization and Optimization: Operational excellence involves mapping out each step in key workflows, eliminating unnecessary tasks, and establishing standardized procedures that reduce variation and errors.

- Data-Driven Decision-Making: Metrics and analytics play a pivotal role in spotting opportunities, predicting trends, and refining strategies over time.

- Empowered Workforce: Cultural aspects—such as leadership, employee engagement, and teamwork—are just as crucial as technology or process design. When team members are empowered to suggest and implement improvements, the entire organization benefits.

Combining these elements creates a framework in which every employee contributes to sustained growth and resilience. Let’s look at how businesses can implement these strategies practically.

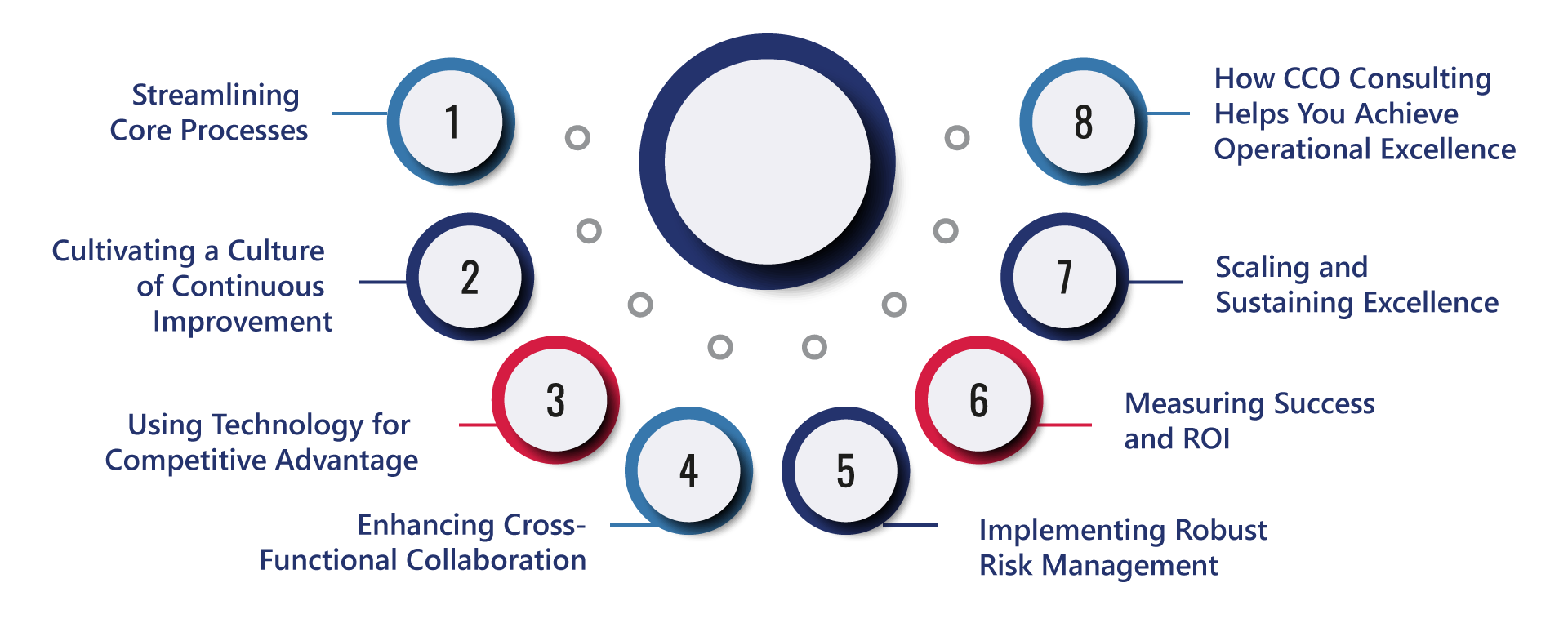

1. Streamlining Core Processes

Process streamlining begins with identifying your most critical workflows, whether it’s supply chain management, service delivery, or cross-departmental collaboration. By mapping out each step in these processes, you can uncover redundancies and roadblocks. A few common ways to streamline processes include:

- Workflow Mapping: Use flowcharts or specialized software to visualize tasks and identify friction points.

- Lean Principles: Adopting lean methodologies (originating in manufacturing but applicable across industries) helps systematically cut out waste, reduce lead times, and improve overall efficiency.

- Process Automation: Tools such as customer relationship management (CRM) platforms, project management software, and robotic process automation (RPA) can automate repetitive tasks and free up human resources for more strategic work.

Pro Tip: Before you automate a workflow, ensure it’s already optimized. Automating an inefficient process will only accelerate poor results. Instead, streamline first, then layer automation on top for maximum impact.

2. Cultivating a Culture of Continuous Improvement

A sustainable shift toward operational excellence requires cultural buy-in across all levels of the organization. It’s not enough to mandate new processes from the top down; employees must be encouraged and empowered to actively participate in identifying areas of improvement.

- Leadership Example: Leaders should model the principles of operational excellence by communicating openly, acknowledging failures as opportunities to learn, and celebrating small wins.

- Employee Engagement: Regular training, brainstorming sessions, and performance reviews that focus on problem-solving can ignite a culture where every team member feels accountable for efficiency and quality.

- Feedback Loops: Encourage cross-functional feedback so that insights from one department can help refine processes or strategies in another. This open dialogue fosters a unified commitment to excellence.

By making continuous improvement part of the organizational DNA, companies can stay agile in a rapidly evolving business landscape.

3. Using Technology for Competitive Advantage

Embracing digital transformation is a critical component of operational excellence in modern business. Technology solutions can streamline processes, elevate data analysis, and provide real-time insights, enabling more proactive decision-making.

- Automation Tools: From simple applications like automated billing to complex tools like AI-driven predictive maintenance, automation can significantly reduce manual errors and speed up routine tasks.

- Cloud Computing: Migrating critical systems to the cloud ensures scalability and reliability, allowing teams to work seamlessly from multiple locations.

- Big Data and Analytics: Sophisticated analytics platforms can mine historical and real-time data for actionable insights—whether forecasting customer demand or optimizing inventory levels.

However, technology alone cannot solve operational issues. A robust implementation strategy that aligns with business goals and involves proper training is essential for realizing genuine return on investment.

4. Enhancing Cross-Functional Collaboration

Operational excellence often stalls when departments function in silos, each optimizing their own piece of the puzzle without considering the broader organizational impact. Cross-functional collaboration ensures alignment across various teams and fosters transparent communication.

- Collaborative Platforms: Utilize project management tools (e.g., Trello, Asana, or Monday.com) that centralize information and make progress visible to all stakeholders.

- Regular Touchpoints: Schedule cross-departmental meetings or stand-ups to discuss challenges, share updates, and align on strategic goals.

- Common KPIs: Define shared key performance indicators that motivate departments to work together rather than pursue isolated objectives.

When departments collaborate effectively, bottlenecks are exposed, resources can be pooled more efficiently, and innovative solutions often emerge as a result of combining diverse skill sets.

5. Implementing Robust Risk Management

In the quest for operational excellence, risk management often takes a back seat. However, identifying and mitigating potential pitfalls is essential for building resilient processes that can withstand market volatility, supply chain disruptions, or technological failures.

- Risk Assessment Framework: Conduct comprehensive assessments to map out potential risks in every major operational area—from logistics to IT infrastructure.

- Mitigation Strategies: Develop contingency plans and allocate resources to address high-impact risks. This could include backup suppliers, redundancies in critical systems, or crisis management protocols.

- Continuous Monitoring: Ongoing vigilance, supported by data analytics, helps spot early warning signs so that you can respond before minor issues escalate into major crises.

Proactively managing risk not only protects the bottom line but also builds trust with customers and stakeholders.

6. Measuring Success and ROI

Without measuring success, it’s challenging to sustain momentum or justify investments in operational excellence. Metrics should align directly with both short-term process improvement goals and long-term strategic objectives.

- Financial KPIs: Examples include cost savings, revenue growth, or improved profit margins.

- Operational Metrics: Lead times, defect rates, and inventory turnover ratios offer insight into efficiency gains.

- Customer-Centric Metrics: Net Promoter Score (NPS), on-time delivery rates, and customer churn rates reveal how process improvements resonate in the marketplace.

- Employee-Focused Metrics: Track employee engagement, retention, or productivity metrics to gauge the impact of your operational excellence initiatives on your workforce.

By benchmarking these metrics before and after key changes, you can illustrate the tangible value of your improvement efforts. This data also guides further refinements, ensuring your organization remains in a cycle of ongoing optimization.

7. Scaling and Sustaining Excellence

Reaching initial targets is a significant milestone, but sustaining excellence requires consistent effort. Organizations that treat operational optimization as a continual journey, rather than a one-off project, are more likely to remain competitive.

- Periodic Audits: Schedule regular audits to revisit processes, confirm compliance with new policies, and measure performance against updated benchmarks.

- Refresher Training: As businesses evolve, so do the skills required for success. Keep employees up to date with the latest tools and methodologies.

- Adaptive Systems: Implement scalable solutions that can flex with fluctuating demand or new market opportunities, allowing you to pivot quickly when conditions change.

- Innovation Ecosystem: Encourage a mindset that embraces experimentation. Pilot programs and research initiatives can uncover cutting-edge strategies that keep you ahead of competitors.

Sustained operational excellence hinges on flexibility and willingness to adapt. When systems, people, and processes are all aligned with that vision, growth becomes a natural outcome rather than a constant struggle.

8. How CCO Consulting Helps You Achieve Operational Excellence

As a leading consultancy, CCO prides itself on delivering data-driven, actionable insights that transform businesses from the inside out. We collaborate closely with our clients to create custom solutions tailored to their unique needs:

- End-to-End Process Analysis: Our experts assess every facet of your current workflows to identify inefficiencies and opportunities for cost savings.

- Strategic Roadmaps: Beyond diagnosing issues, we outline clear action plans complete with milestones, resource allocations, and timeline estimates.

- Technology Integration: From selecting the right tools to implementing automation and analytics platforms, we guide you through digital transformation.

- Cultural Alignment: Achieving true operational excellence demands organizational unity; we facilitate training sessions, leadership workshops, and team-building initiatives to foster a culture of continuous improvement.

- Performance Tracking: We establish measurable KPIs and monitor them over time, ensuring that improvements deliver lasting benefits and a strong ROI.

Our goal is not just to solve one-off problems but to equip you with the frameworks and capabilities needed to maintain operational excellence long after our engagement ends.

Case Study Snapshot: From Bottlenecks to Breakthroughs

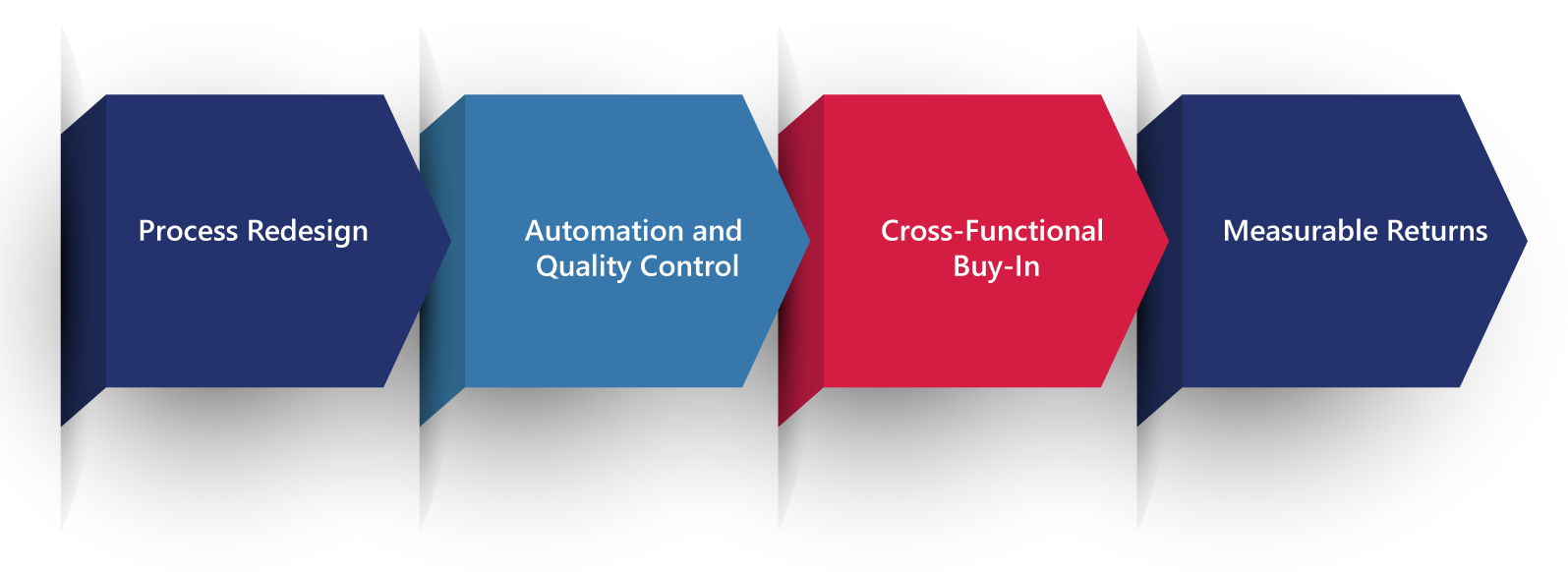

Imagine a mid-sized manufacturing firm with growing demand for its products. Despite strong market opportunities, frequent bottlenecks, high defect rates, and siloed communication hinder its ability to scale effectively. After engaging CCO Consulting:

- Process Redesign: We mapped out the production line, identified redundant steps, and implemented lean techniques, reducing lead times by 25%.

- Automation and Quality Control: Automated checkpoints replaced manual inspections at critical junctures, slashing defect rates by 40%.

- Cross-Functional Buy-In: Regular communication forums brought stakeholders from procurement, production, and quality assurance together, resulting in smoother coordination and faster decision-making.

- Measurable Returns: Over 12 months, the company reported significant cost savings and a new agility that allowed it to seize emerging market opportunities.

This case highlights the transformational impact of combining strategic planning, technological adoption, and a culture of continuous improvement.

Final Thoughts: Embrace Excellence for Long-Term Success

Operational excellence is more than a buzzword—it’s an ongoing commitment that can revolutionize your organization’s performance, resilience, and growth potential. While the journey may seem daunting, the rewards are immense: streamlined processes, empowered teams, delighted customers, and a bolstered bottom line.

Here at CCO, we believe that any organization—no matter the size or industry—can achieve operational excellence with the right blend of strategy, culture, and technology. By following the steps outlined in this article, you can begin laying the groundwork for a more efficient, dynamic, and future-proof business.

Ready to unlock operational excellence? Reach out to our team of experts today and discover how we can help you implement data-driven strategies that optimize your workflows, elevate your customer experience, and drive sustainable growth for years to come. Let’s work together to set your business on a path toward lasting success.